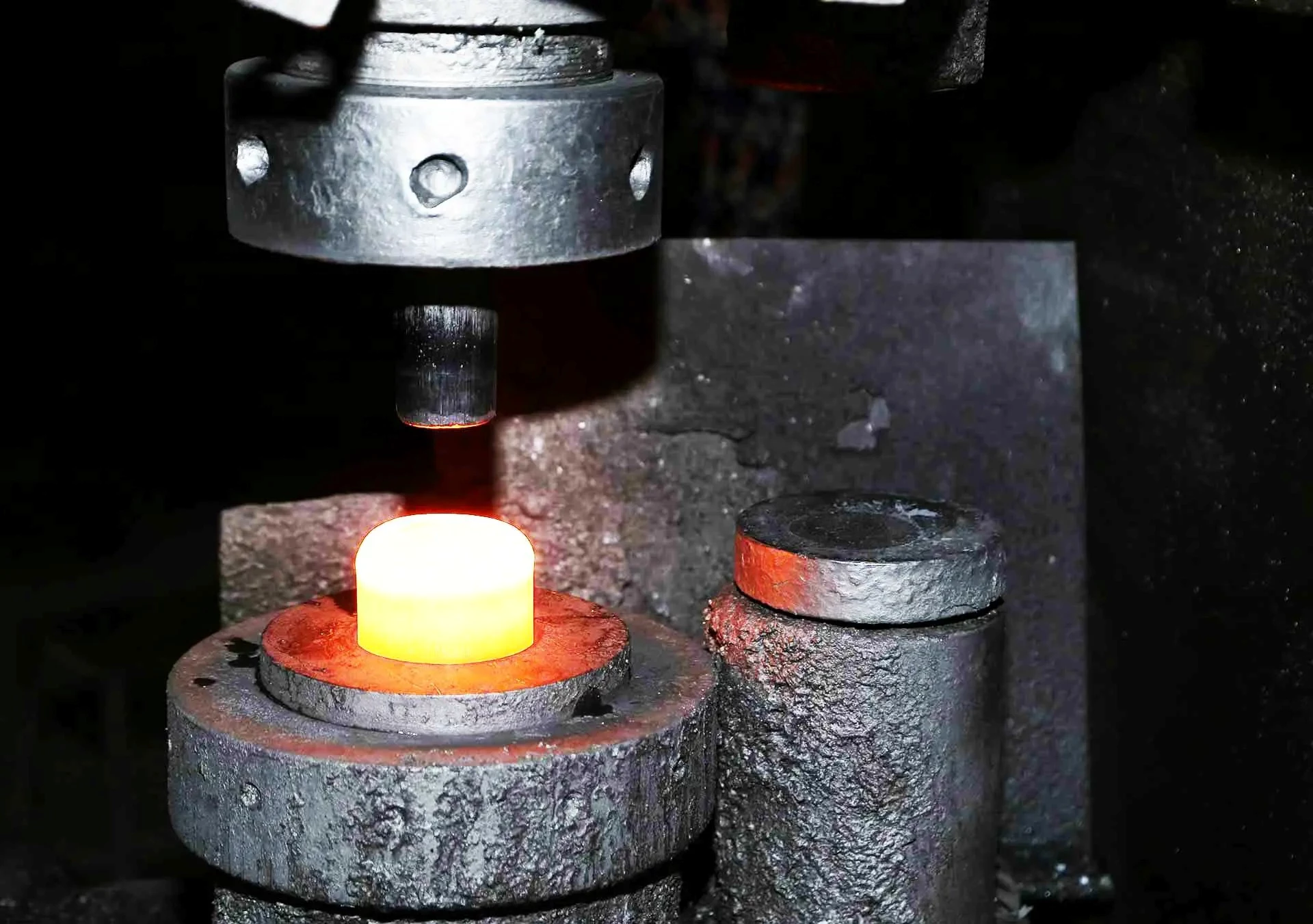

Valve Ball Forging

Forged valve ball are designed and manufactured to provide maximum service life and dependability includes premium features and special options that deliver performance and longevity in the most demanding applications. All balls can meet the design requirements of standard API 608 & API 6D,British standard BS 5351 . Our balls are available in a complete range of materials Standard materials include generally used grades of carton steel, stainless steel, CF8, CF8M, 304, 316, 1.4401, 1.4301, carbon steel, nickel plating, chromium plating. we provide both full bore and reducing bore. Reduced-bore design provides exceptional flow control.

Advantage

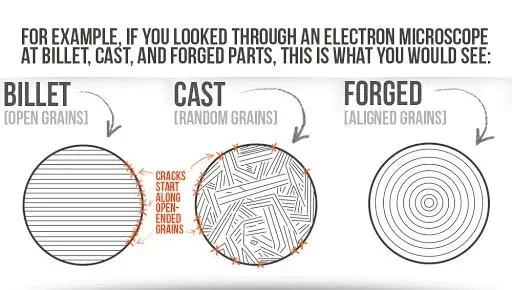

Forged balls are used widely because of its plenty of advantages, like high toughness, smooth surface, good wear-resistance and impact resistance, low breakage and lost round rate. Hot rolling and forging technique can effectively avoid internal porosity which is common in casting. For keeping complete line construction of metal, the mechanical performance of forging ball is generally superior to casting ones.

|

Forging |

Casting |

Key Benifits

With any financial product that you buy, it is important that you know you are getting the best advice from a reputable company as often you will have to provide sensitive information online or over the internet.

Do I have to commit to a contract?

With any financial product that you buy, it is important that you know you are getting the best advice from a reputable company as often you will have to provide sensitive information online or over the internet.

What Payment Methods Are Available?

With any financial product that you buy, it is important that you know you are getting the best advice from a reputable company as often you will have to provide sensitive information online or over the internet.