Zirconium valve ball forging process

Zirconium valve ball forging process

1. An overview

Zirconium is a very active chemical element, metal zirconium under room temperature surface generation a layer of protective oxide film, so in the air is very stable, and air oxygen, nitrogen almost no reaction. The passivating film has high corrosion resistance and good corrosion resistance in most organic acids, inorganic acids, strong alkalis, molten salts, high temperature water and metals. Therefore, zirconium material in petroleum, chemical industry, nuclear power, aerospace and other fields have been widely used, zirconium valve has also been more and more users of the favor.

Recently, our company undertook a petrochemical company a large number of wrong material valves, ball valves occupy a large proportion, Especially the ball forging. Choosing a reasonable forging process can not only save the cost of materials, but also bring convenience for the later processing and manufacturing, greatly reducing the cost of labor.

2. Process analysis

(1) Process performance:

Zirconium and zirconium alloy compared with alloy steel and aluminum, weldability is better, can carry on fusion welding; brazing; explosion welding, zirconium weldability are similar with titanium. The elastic modulus of zirconium is low and the residual stress after welding is small. Zirconium forging performance is similar to titanium material, zirconium material can not use gas cutting off material, the initial forging temperature is about 1000 degrees Celsius, the final forging temperature is above 800 degrees Celsius. Forging temperature range is narrow, complete annealing temperature is 675-800 ℃, incomplete annealing temperature is 600 ℃.Annealing may be performed in a weak oxidizing or neutral atmosphere. High temperature annealing of thin parts is best performed in a vacuum. Zirconium material at 865 degrees Celsius is a closely arranged hexagonal lattice phase, above 865 degrees Celsius is a body centered cubic lattice phase. The final annealing of zirconium should be conducted below the phase transition temperature.

Zirconium material processing hardening tendency is obvious, machining should use slow speed, large feed, and a lot of cutting fluid. The cutter is usually made of hard alloy or high-speed steel, and the grinding wheel is made of silicon carbide. The power consumption is about 3/4 of that of processed carbon steel. Zirconium chips are easy to catch fire during cutting, so they should be stored in containers with water.

(2) Ball forging scheme

The sphere is a regular special-shaped part, and its forming method can only use mold, so the zirconium sphere is forged by mold, which is convenient for forming and mechanical processing, and saves cost.

This set of die adopts split structure, which is simple in structure and easy to operate. It is composed of upper and lower die and final forging core. The inner cavity of upper and lower die is designed into a sphere, which is processed and formed on the CNC lathe. The outer circle of the core is designed into a cone, which is easy to die. At the same time, in order to increase the hardness of the sphere, the surface quenching treatment is needed for each part of the mold after the processing is completed. In addition, considering the forging operation with manipulator control, so, the surface should have the corresponding plus flat surface.

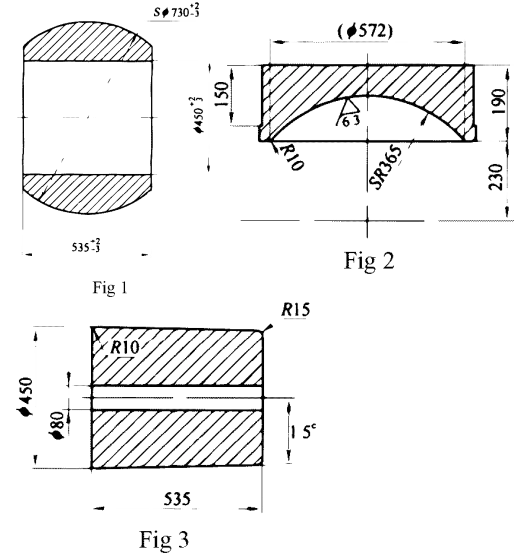

(3) Mold design Mold size should be consistent with the technological size of the sphere to ensure the forming size of the sphere, as shown in Figure 1-3.

(4) Quality control of raw materials; The raw material is sponge zirconium, which is smelted into round ingot by secondary vacuum to avoid the defects in the raw material causing forging cracking. After the raw material surface is rented and processed, ultrasonic testing shall be carried out and selected after passing the test, as shown in Figure 4-5.

3. Forging process

(1) Process parameters are shown in the attached table.

(2) Process

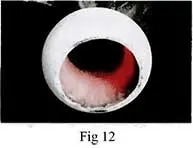

Clearing slag (to prevent the pollution of zirconium) and heating (before furnace charging, preheat to 400 degrees Celsius, and then slowly heated to 980 degrees Celsius, die preheat to 400 degrees C) – insulation 2 h – pier, chamfering (a fire after forging, pier thick then long pull, improve its mechanical properties, as shown in figure 6 and figure 7) and punching (lower punch for punch, see figure 8) – oven heating (up to 950 degrees Celsius, heat preservation, 1.5 h) and two fire forging (upper die clingy billet, hole in the ball core shaft, reaming) – > again oven (up to 950 C, Heat preservation for 1.5h)→ three-fire forging (set die and reaming, see Figure 9) → flat two sides (the ball rotates 900, level two end faces, see Figure 10) → return to furnace again (temperature rises to 950.C, heat preservation for 1.5h)→ Upper end forging core, set upper and lower die, precision forging sphere (the upper and lower sides of the sphere are in the mold cavity, final forging is formed, see Figure 11 and 12).

Execution process parameters

Category |

Forging equipment |

Heating equipment |

Operating equipment |

Initial forging temperature |

Finish forging temperature |

The deformation |

Height to diameter ratio |

Requirements |

12MN Hydraulic press |

resistance furnace |

Hydraulicefficiency operated manipulator |

1000-980 |

850 |

≤30 |

1.5-2 |