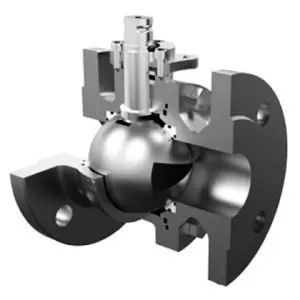

Ball Valve

Ball valve Ball valve, opening and closing part (valve ball) driven by the valve stem and rotating around the ball valve axis. Can also be used for fluid regulation and control, hard sealing V-type ball valve v-type ball core and hardfaced metal valve seat has a strong shear force, especially suitable for containing fiber, small solid particles and other media. The multi-pass ball valve in the pipeline can not only flexibly control the confluence of media, shunt, and flow direction switch, but also close any channel and make the other two channels connected. This class of valves should generally be installed horizontally in the pipeline. Ball valves are divided into pneumatic ball valves, electric ball valves and manual ball valves. Driving mode Manual, electric, pneumatic, hydraulic applications in the field of food, chemical, petroleum, electric, and other operating principles of the valve stem drive rotary movement around the ball valve

Directory

1 Product Introduction 2 the characteristics of 3 classification ▪Functional classification ▪ Transmission classification ▪ Classification Features 4 Product Features 5 Parameter grade 6 Pressure limit ▪ Failure resolution ▪ Installation use ▪ Hard seal installation ▪ Suitable Occasion ▪ Operational use 7 Daily Maintenance 8 Matters needing Attention 9 Advantages and disadvantages

Product Introduction Ball Valve appeared in the 1950s, with the rapid development of science and technology, the continuous improvement of production process and product structure, in just 40 years, has rapidly developed into a major valve class. In the western industrial developed countries, the use of the ball valve is increasing year by year. In Our country, the ball valve is widely used in petroleum refining, long – term pipeline, chemical industry, papermaking, pharmaceutical, water conservancy, electric power, municipal, steel and iron and other industries, occupy a pivotal position in the national economy. It has a rotation motion of 90 degrees. The body of the cock is a sphere with a circular through hole or channel passing through its axis. The ball valve in the pipeline is mainly used to cut off, distribution and change the flow direction of the medium, it only needs to use a rotation of 90 degrees of operation and a small torque to close tight. Ball valve is most suitable for switch, cut off valve use, V – type ball valve. In addition to paying attention to pipeline parameters, electric valves should also pay special attention to the use of environmental conditions, because the electric device in the electric valve is an electromechanical equipment, its use state by its use environment. In general, electric ball valve, butterfly valve in the following environment to use special attention. The characteristics

A. wear-resisting; Because the hard seal ball valve spool is alloy steel spray welding, sealing ring is alloy steel surfacing welding, so hard seal ball valve in the switch will not produce too much wear.(Its hardness coefficient I s 65-70) : B. Good sealing performance; Due to the hard seal ball valve seal is artificial grinding, until the spool and seal ring can be used. So its sealing performance is reliable. C. Light switch; Because the hard sealing ball valve seal ring bottom USES the spring to make the seal ring and the spool tightly hold together, so in the outside force exceeds the spring pretension when the switch is very light. D. Long service life: it has been widely used in petroleum, chemical industry, power generation, paper making, atomic energy, aviation, rocket and other sectors, as well as People’s Daily life. Pneumatic ball valve structure is simple and compact, reliable sealing, convenient maintenance, sealing surface and sphere are often in a closed state, not easy to be eroded by the medium, easy to operate and maintain, suitable for water, solvent, acid and natural gas and other general working medium, mainly used to cut off or connect the medium in the pipeline, can also be used for fluid regulation and control.

Compared with other kinds of valves, pneumatic ball valves have angular stroke output torque, fast opening, stable and reliable, widely applicable, and the following advantages:

1. The thrust bearing reduces the friction torque of the valve stem for smooth and flexible long-term operation. 2. Anti-static function: spring is set between the ball, valve stem and valve body to export the static electricity generated in the switching process. 3. Due to the good self-lubrication of PTFE and other materials, the friction loss with the ball is small, so the service life of pneumatic ball valve is long. 4. Small fluid resistance: pneumatic ball valves are all valve classification in the fluid resistance of the least one, even if the diameter of the pneumatic ball valve, the fluid resistance is quite small. 5. Reliable stem seal: because the stem only rotation movement and do not do lifting movement, the stem packing seal is not easy to destroy, and the sealing ability increases with the increase of media pressure. 6. Good seat sealing performance: the sealing ring made of polytetrafluoroethylene and other elastic materials is easy to seal, and the sealing ability of pneumatic ball valve increases with the increase of medium pressure. 7 small fluid resistance, full size of the ball valve is basically no flow resistance. 8. Simple structure, small size and light weight. 9. Be tight and reliable. It has two sealing surface, and the ball valve sealing material widely used in various plastics, good sealing, can achieve complete sealing. It has also been widely used in vacuum systems. 10. Easy operation, fast opening and closing, rotation of 90° from full open to full close, convenient for remote control. 11. Convenient maintenance, simple ball valve structure, sealing ring is generally active, dismantlement and replacement are relatively convenient. 12. When fully open or fully closed, the sealing surface of the ball and seat is isolated from the media, which will not cause erosion of the valve sealing surface when passing through. 13. Wide range of applications, sizes from small to a few millimeters, large to a few meters, from high vacuum to high pressure can be applied. 14. Ball valves can be used in media with suspended solid particles because of their wiping property during the opening and closing process. 15. High machining precision, high cost, not suitable for use in high temperature, such as impurities in the pipeline, easy to be blocked by impurities, resulting in the valve can not be opened.

Functional classification

1. Bypass valve: The ball valve is generally opened with still water, so the bypass valve is set to press flat first, that is, fill both sides with water; 2. Air valve: When filling water, remove the air and take the buoy to close the valve by yourself; When discharging water, replenish air and the buoy will descend by itself; 3. Pressure relief valve: When opening and closing the valve, remove the pressure water between the valve and the sealing cover, so as not to wear the sealing cover; 4. Sewage valve: discharge the sewage in the lower part of the ball shell. Transmission classification 1, pneumatic ball valve 2. Electric ball valve 3, hydraulic ball valve 4, gas hydraulic ball valve 5, electric hydraulic ball valve 6, turbine drive ball valve

Classification characteristics Ball valves are: floating ball valve, fixed ball valve, track ball valve, V-type ball valve, tee ball valve, stainless steel ball valve, cast steel ball valve, forged steel ball valve, ash ball valve, anti-sulfur ball valve, pneumatic ball valve, electric ball valve, clip ball valve, welding ball valve. According to the material classification of the shell/main body, the ball valve can be divided into:

1. Metal valve: such as carbon steel valve, alloy steel valve, stainless steel valve, cast iron valve, titanium alloy valve, Monel valve, copper alloy valve, aluminum alloy valve, lead alloy valve. 2. Metal body lining valve: such as rubber lined valve, fluorine lined valve, lead lined valve, plastic lined valve, lined enamel valve. 3. Non-metallic material valve: such as ceramic valve, glass valve, plastic valve.

Domestic production of ball valve manufacturers more, the connection size is mostly not uniform. Mainly divided into the following categories: The ball valve of the ball is floating, under the pressure of the medium, the ball can produce a certain displacement and pressed on the end of the sealing surface, to ensure that the end of the export seal. Structure Good sealing, but the ball bearing the working media of all the load to the export sealing ring, so it should be considered whether the sealing ring material can withstand the working load of the ball media, in higher pressure impact, the ball may occur deviation. This structure is generally used for low and medium pressure ball valves. The ball of the ball valve is fixed and does not move under pressure. Fixed ball and ball valves are equipped with floating seats, which, subject to medium pressure, cause the seat to move so that the sealing ring is pressed tightly on the ball to ensure the sealing. Bearings are usually mounted on the upper and lower shafts of the spheroidal valves, with small operation twist, suitable for high pressure and large diameter valves. In order to reduce the operating torque of the ball valve and increase the reliability of sealing, and appeared oil sealing ball valve, both in the seal between the injection of special lubricating oil, in order to form a layer of oil film, that is, to enhance the sealing, and reduce the operating torque, more suitable for high pressure large diameter ball valve The elastic The ball valve is ball elastic. Ball and seat sealing ring are made of metal materials, sealing pressure is very high, depending on the medium itself The pressure is not up to the sealing requirement, external force must be applied. This valve is suitable for high temperature and high pressure media. The elastic sphere is obtained by cutting an elastic groove at the bottom of the inner wall of the sphere. When closing the channel, use the stem wedge to inflate the ball and seat to seal. Loosen the wedge before turning the ball, and the ball returns to its original shape, creating a small gap between the ball and the seat to reduce friction on the sealing surface and operating torque. Qv347, Qv647, Qv947 V regulating ball valve Qv347, Qv647, Qv947 V regulating ball valves have shear action on the seat due to the ball core with V-shaped structure. Therefore, it is suitable for the control of relevant technological parameters in suspension medium containing fiber or micro solid particles in papermaking, chemical industry, metallurgy and other industrial enterprises. It is especially suitable for the automatic regulation of the fluid of suspended particles such as pulp, white water, black liquid and white liquid in the process of pulping and papermaking and the medium of thick and muddy liquid. This V-type ball valve belongs to the fixed ball valve, is also a single seat sealed ball valve, regulating performance is the best ball valve, flow characteristics is equal percentage, adjustable ratio up to 100:1.Its V-cut and metal seat between shear action, especially suitable for containing fiber, micro solid particles, slurry and other media Three-way ball valves are T – and L-shaped. The T shape can make the three orthogonal pipelines connect with each other and cut off the third channel, playing the role of diversion and confluence. L-type can only connect two orthogonal pipelines, and cannot maintain the interconnection of the third pipeline at the same time, and only plays the role of distribution. Product features

1. Three-way ball valve adopts integrated structure in structure, sealing type of 4-face seat, less flange connection, high reliability, design and realization of lightweight. 2. Tee ball core is divided into T type and L type, with long service life, large circulation capacity and small resistance. 3, the ball valve according to the action type of single action and double action two types, single action type is characterized by once the power source failure, the ball valve will be in the control system requirements of the state.

Advantages:

1.The fluid resistance is small, and the resistance coefficient is the same as the length of the pipe section. 2.Simple structure, small size and light weight. 3.Compact and reliable, and the ball valve sealing material is widely used in plastic, good sealing, in the vacuum system has also been widely used. 4.Easy to operate, fast open and close, from full open to full close only rotation 90°, convenient for remote control. 5.Easy maintenance, simple ball valve structure, sealing ring is generally active, disassembly and replacement are more convenient. 6.Wide range of applications, sizes from small to a few millimeters, large to a few meters, high vacuum or high pressure can be used.

This kind of valve is the high pressure ball valve commonly used in the existing mine. It bears high pressure and adopts u-type fast connection, which can realize rapid installation and disassembly in the daily production and use of the mine and is convenient for use. The ash discharging ball valve is mainly used to cut off, distribute and change the flow direction of medium in the pipeline. Ash discharging ball valve can be divided into: floating ball type, fixed ball type, elastic ball type. Ash discharging ball valve is mainly used to cut off or connect the medium in the pipeline, can also be used for fluid adjustment and control, compared with other valve types, ash discharging ball valve has angular stroke output torque, open quickly, stable and reliable, widely applicable. The dust ball valve works by rotating the valve to keep the valve smooth or blocked The structure of the electric ball valve is only composed of a few parts, which saves data consumption. Small size, light weight, small installation size electric ball valve structure diagram, small driving torque, pressure regulating valve, easy to operate, agile, just rotate 90° can be quickly open and close; And also has a good flow regulation effect and sealing characteristics, in large and medium diameter, low pressure application category, electric ball valve is the leading valve situation. Electric ball valve in a complete open position, the thickness of the disc is the resistance of the medium through the valve body, so the pressure drop through the valve is very small, so it has a good flow control characteristics. The electric ball valve has two sealing types: ball seal and metal seal. Resilient seal valve, seal ring can be embedded in the body or attached to the disc periphery. Adopt the valve of metal seal general than the valve of elastic seal long life, but it is difficult to achieve complete seal. Metal seal can adapt to higher working temperature, elastic seal has a temperature limit of the point. If the request electric ball valve is used as flow control, it is important to accurately select the size and type of valve. The construction principle of electric ball valve is especially suitable for manufacturing large diameter valve. Electric ball valve is not only widely used in petroleum, gas, chemical industry, water treatment and other general industries, but also used in the cooling water system of thermal power stations. Commonly used electric ball valve has two kinds of electric ball valve and flange type. Double-head bolt is used to connect the valve between the two pipe flanges. Flange type electric ball valve is a valve with a flange, and the two ends of the valve are connected to the pipe flange with the bolt. The strength of the valve is the valve under medium pressure. Valves are mechanical products subject to internal pressure and must have sufficient strength and stiffness to ensure long-term use without breaking or deformation. Pneumatic ball valve is composed of ball valve equipped with pneumatic actuators, pneumatic actuators are divided into double-acting pneumatic actuators and single-acting pneumatic actuators, through the solenoid valve control, to achieve the ball valve switch action. Pneumatic ball valve can realize intelligent control, quickly open or close the pipeline, can effectively control and manage the pipe network. Parameter level

1. Nominal pressure or pressure level: PN1.00-32.0mpa, ANSI CLASS 150-900, JIS10-20K; 2. Nominal diameter or diameter: DN6 ~ 900, NPS 1/4 ~ 36; 3. Connection mode: flange, butt welding, thread, socket welding, etc. 4. Applicable temperature: -196℃ ~ 540℃; 5. Driving mode: manual, worm and worm drive, pneumatic, electric, hydraulic, gas-liquid linkage, electro-hydraulic linkage; 6. Valve body materials: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8(304), CF3(304L), CF8M(316), CF3M (316L), Ti. Different materials can be used for water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media.

Pressure limit The nameplate shows the maximum operating pressure allowed for the ball valve at the maximum and minimum operating temperatures. For seats and seals made of PTFE or RTFE, the operating temperature of other types of seats and seals shall be checked by KI factory. The nominal pressure class (PN) of the valve indicates the maximum operating pressure of the valve at normal temperature.(For example, PN4.0 indicates that the maximum working pressure at -190C ~ 380C is 40 Bar(4.0mpa)). For electric or pneumatic actuators, please refer to their corresponding instructions. Failure to solve The ball valve has been scoured by the material for a long time, causing friction and serious impact wear, which cannot meet the normal production and shorten the service life of the equipment. At present, the ball valve wear more wear-resistant materials, such as ceramic materials, polymer composite materials and other methods, the application of more technical systems. The polymer material has superior adhesion, super abrasion resistance, safety to solve the metal often wear defects, ensure the normal production of enterprise equipment. Moreover, the unique ceramic materials and special surface intensifiers in the material make its wear resistance and physical impact resistance better than any steel or even ceramic tile in the worst dry grinding environment. The product’s incompatibility with coal is an ideal material to prevent coal accumulation. Install and use

1. Indoor device or outdoor application with protective mode; 2. Outdoor and open-air installation, wind, sand, rain, sunshine and other erosion; 3. Flammable, explosive gas or dust environment; 4. Environment in humid tropics and dry tropics; 5. The medium temperature of the pipeline is as high as 450℃ and above; 6. Ambient temperature below -20℃; 7. Be subject to flooding or flooding; 8. Environment with radioactive material (nuclear power plant and radioactive material test facility); 9. The environment on the ship or dock (salt spray, mold, moisture); 10. Occasions with violent vibration; Occasions prone to fire;

For the electric ball valve in the above environment, its electric device structure, material and protection method are different. Therefore, the corresponding valve electric device should be selected according to the above obligation environment. According to the engineering control requirements, for the electric ball valve, its control function is completed by the electric device. The purpose of the application of electric ball valve is to open, close and adjust the valve linkage to complete non-manual electrical control or computer control. The use of electric devices is no longer just for frugality. Because the function of product of different manufacturer and quality differ greatly, accordingly, choice electric device and choice place match valve are equally important to the project. Because the requirement of industrial automation level rises all the time, on the one hand to electric valve should amount more and more, on the other hand to electric valve control requirement also is higher and higher, more and more complex. So electric valves in the electrical control aspects of the design is always updated. Along with the use request unceasing enhancement and the computer popularization application, the new type, the diversity electrical control way will appear from beginning to end. To the electric valve overall control consideration, should pay attention to select the electric valve control mode. For example, according to the engineering needs, whether to apply the centralized control mode, or a single control mode, whether to interact with other equipment, sequence control or the application of computer sequence control, etc., the control principle is different. Only standard electrical control principle is given in the sample of the valve electric device manufacturer, so the application department should make technical disclosure with the electric device consumer factory to make technical requirements clear. Hard seal installation

1) Remove the protection cover on both sides of the flange end and rinse the valve when it is fully open. 2) Before installation, the complete machine shall be tested according to the specified signals (electricity or gas) (to prevent vibration affecting the performance due to transportation), and on-line installation shall be carried out after passing (wiring shall follow the circuit diagram of electric actuator). 3) Flush and remove any remaining impurities (which may damage the seat and ball) from the pipe before preparing to connect with the pipe. 4) During installation, please do not use the actuator part of the valve as the lifting point to avoid damage to the actuator and accessories. 5) The valve shall be installed in the horizontal or vertical direction of the pipeline. 6) The pipeline near the installation point should not sag or bear external forces. Pipe supports or supports can be used to eliminate the deviation of the pipeline. 7) After connecting with the pipe, cross lock the flange connection bolt with the specified torque.

Applicable occasions Since ball valves are usually made of rubber, nylon, and polytetrafluoroethylene as seat ring materials, their service temperature is limited by seat ring materials. Ball valves stop by the action of the metal ball in the medium, the plastic seat between the pressure to complete (floating ball valve).Under certain contact pressure, elastoplastic deformation occurs in local area. This deformation can compensate the precision and surface roughness of the ball and ensure the sealing performance of the ball valve. And because the ball valve seat sealing ring is usually made of plastic, so in the selection of the ball valve structure and performance, to consider the ball valve fire resistance and fire, especially in the petroleum, chemical, metallurgical and other departments, in flammable, explosive medium equipment and pipeline system using the ball valve, more attention should be paid to fire resistance and fire. Generally, ball valves are recommended in pipeline systems with double position regulation, strict sealing performance, mud, wear, shrink opening and closing channels, rapid opening and closing (1/4 turn opening and closing), high pressure cut-off (large pressure difference), low noise, cavitation and gasification phenomena, small leakage into the atmosphere, small operating torque and small fluid resistance. Ball valves are also suitable for light construction, low pressure cut-off (low pressure difference), corrosive medium pipeline system. Ball valves can also be used in cryogenic (cryogenic) devices and piping systems. In the oxygen pipeline system of metallurgical industry, strict degreasing treatment is required for ball valves. Full size welded ball valves shall be used in oil and gas pipelines where the main line shall be buried underground. In the request has the regulation performance, must choose the special structure with the V-shape opening ball valve. In petroleum, petrochemical, chemical, electric power, urban construction, the working temperature of more than 200 degrees of pipeline system can choose metal to metal sealing ball valve. Operation

1) Make sure that pipelines and valves have been flushed before operation. 2) The valve operation is completed according to the input signal of the actuator to drive the stem rotation: when the valve is rotated 1/4 turn forward (90°), the valve is turned off. Valve opens by reversing rotation 1/4 turn (90°). 3) When the arrow indicating the direction of the actuator is parallel to the pipeline, the valve is in an open state; The valve is closed when the indicating arrow is perpendicular to the line.

Daily maintenance Having a long service life and maintenance free period will depend on normal working conditions, maintaining a harmonious temperature/pressure ratio, and reasonable corrosion data Ball valve in the closed state, there is still pressure fluid inside the valve body Before servicing: relieve line pressure and keep valve in open position; Disconnect the power supply or air source; Detach actuator from support It is necessary to make sure that pressure has been removed from the upper and downstream pipes of the ball valve before disassembly and disassembly operation Care must be taken to prevent damage to the sealing surface of the parts, especially non-metallic parts, and special tools should be used when removing the O-ring The bolts on the flange must be tightened symmetrically, step by step and evenly during assembly Cleaning agent should be compatible with rubber parts, plastic parts, metal parts and working medium (such as gas) in ball valve. When the working medium is gas, the metal parts can be cleaned with gasoline (GB484-89).Non-metallic parts shall be cleaned with purified water or alcohol The non-metallic parts should be removed from the cleaning agent immediately after cleaning, and should not be soaked for a long time After cleaning to be washed wall surface cleaning agent volatilization (can not be soaked in cleaning agent of silk cloth wipe) assembly, but not for a long time, otherwise it will rust, dust pollution New parts also need to be cleaned before assembly No contamination, adhesion or retention on the surface of the parts or into the inner cavity shall be allowed during assembly, such as metal debris, fiber, grease (except for specified use) and other impurities and foreign matter, etc. In case of microleakage in the packing, the stem nut shall be re-locked. Note: Do not lock too tight, usually lock 1/4 turn ~ 1 turn, leakage will stop.

A), Remove Keep valve in half open position to flush and remove any hazardous substances that may exist inside and outside the valve body. Close the ball valve, remove the connecting bolts and nuts from the flanges on both sides, and remove the valve completely from the line. Remove drive assembly – actuator, connection bracket, release washer, stem nut, butterfly shrapnel, gnam, wear plate, stem packing in sequence. Remove cover coupling bolts and nuts, separate cover from body and remove cover washer. Make sure the ball is in the “off” position to easily remove it from the body and then remove the seat. Push stem down through body center hole until completely removed, then remove O-ring and stem underpacking. Caution: Use caution to avoid chafing stem surface and body stuffing box seal. B) Reassemble Clean and inspect disassembled parts and it is highly recommended to replace seals such as seat and bonnet gaskets with a spare part pack. Assemble in reverse order of disassembly. Cross-lock flange connecting bolts with specified torque. Lock stem nut with specified torque. After installing the actuator, input the corresponding signal and rotate the spool by rotating the stem to bring the valve to the open and close position. If possible, perform pressure seal test and performance test on valves according to relevant standards before piping is refitted.

1, Principle The opening and closing part of a ball valve is a ball that rotates about the center line of the body to open and close a valve. 2. Applicable place Low pressure, small diameter pipe used to cut off water flow and change the distribution of water flow or need to open and close quickly. 3, Characteristics

1) Low flow resistance; 2) Simple structure; 3) Small size and light weight; 4) The sealing surface material of the ball valve is plastic with good sealing; 5) Convenient operation, fast opening and closing, convenient for remote control; 6) Convenient maintenance, sealing ring is generally movable, easy to remove and replace; 7) When fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the media, which will not cause the erosion of the valve sealing surface.

4, Classification,

1), commonly used ball valve according to its working principle is divided into floating ball valve, fixed ball valve, lifting lever ball valve. 2) Ball valve can be divided into straight-through type, three-way type and right-angle type according to its channel position. The latter two ball valves are used to distribute the medium and change the flow direction of the medium.

5. Key points of construction and installation

1) The installation position, height and import and export direction must meet the design requirements, and the connection shall be firm and tight. 2) The handle of all kinds of manual valves installed on the insulation pipe shall not be down. 3) The appearance of the valve must be inspected before installation. The nameplate of the valve should conform to the provisions of GB 12220 in the current national standard “Universal Valve Mark”. For valves whose working pressure is greater than 1.0mpa and whose function is to cut off the main pipe, strength and strict performance tests should be carried out before installation, and qualified before use. In the strength test, the test pressure shall be 1.5 times of the nominal pressure, the duration shall not be less than 5min, and the valve shell and packing shall be qualified without leakage. In the tight test, the test pressure is 1.1 times of the nominal pressure; The test pressure shall meet the requirements of GB 50243 for the duration of the test, and the disc sealing surface shall be considered as qualified if there is no leakage. 4) Sealing gasket shall be installed between the valve flange and pipeline flange according to the design requirements of pipeline. 5) Ball valve with transmission mechanism shall be installed according to the provisions of the product operation manual.

6. Implementation standards

1) Product standards “Universal Valve Flanges and butt welded Steel ball Valves” GB/T12237-2007 General Requirements for Steel Valves, GB/T 12224-2005 Standard for Safety Evaluation of Equipment and Protective Materials for Drinking Water Transmission and Distribution GB/T 17219-1998 2) Engineering standards Code for Acceptance of Construction Quality of Building Water Supply, Drainage and Heating Engineering GB 50242-2002 Code for Acceptance of Construction Quality of Ventilation and Air Conditioning Engineering GB 50243-2002

Matters needing attention

(1) The upper and downstream pipelines of the ball valve must be confirmed to have removed the pressure before disassembly and decomposition can be carried out. (2) The non-metallic parts shall be immediately removed from the cleaning agent after cleaning, and shall not be soaked for a long time. (3) Bolts on the flange must be tightened symmetrically, step by step and evenly during assembly. (4) The cleaning agent should be compatible with rubber parts, plastic parts, metal parts and working medium (such as gas) in the ball valve. When the working medium is gas, the metal parts can be cleaned with gasoline (GB484-89).Non-metallic parts shall be cleaned with purified water or alcohol. (5) The decomposed parts of each single ball valve can be cleaned by soaking. The metal parts that still remain undecomposed non-metallic parts can be scrubbed with a clean, fine and clean silk cloth impregnated with cleaning agent (to avoid fiber shedding and sticking to the parts).Remove grease, dirt, glue and dust that adhere to the wall surface during cleaning. (6) During the decomposition and reassembly of the ball valve, care must be taken to prevent damage to the sealing surface of the parts, especially non-metallic parts. Take out the O-ring and use special tools. (7) After cleaning, it shall be assembled after the cleaning agent volatilizes on the washed wall surface (the silk cloth that is not soaked in the cleaning agent can be wiped), but it shall not be used for a long time, otherwise it will rust and be polluted by dust. (8) New parts also need to be cleaned before assembly. (9) Lubricate with grease. Grease shall be compatible with metal material, rubber parts, plastic parts and working medium of ball valve. When the working medium is gas, such as T 221 grease may be used. Apply a thin layer of grease on the surface of the sealing groove, a thin layer of grease on the rubber seals, and a thin layer of grease on the sealing surface and friction surface of the valve stem. (10) There shall be no contamination, adhesion or retention on the surface of the parts or entry into the inner cavity by metal debris, fiber, grease (except for the prescribed use) dust and other impurities and foreign matter during assembly.

Advantages and Disadvantages Advantages:

(1)Has the lowest flow resistance (actually 0); (2) can be used reliably in corrosive media and low boiling point liquids because it will not get stuck when working (in the absence of lubricants); (3) In the larger pressure and temperature range, can achieve complete sealing; (4) Can realize fast opening and closing, some structure opening and closing time is only 0.05~0.1s, in order to ensure that it can be used in the test bench automation system.Quick opening and closing valve, no impact in operation. (5) The spherical closing member can be automatically positioned on the boundary position; (6) The working medium is sealed on both sides reliably; (7) In full open and full close, ball and valve seat sealing surface and media isolation, so high speed through the valve medium will not cause sealing surface erosion; (8) Today’s compact structure, light weight, it can be considered to be the most reasonable valve for low temperature media system; (9) Pet-type valve body symmetrical, especially welded valve body structure, can withstand the stress from the pipe; (10) The component can withstand the pressure difference when it is closed. (11) all welded valve body of the ball valve, can be buried in the ground, so that the inner parts of the valve is not corroded, the maximum service life can be up to 30 years, is the oil and gas pipeline the most ideal valve.

Disadvantages:

(1) because the ball valve seat sealing ring is the most important material is polytetrafluoroethylene, it is inert to almost all chemical substances, and has a small coefficient of friction, stable performance, not easy to aging, wide range of temperature application and sealing performance is good comprehensive characteristics. But PTFE’s physical properties, including high coefficient of expansion, sensitivity to cold flow, and poor thermal conductivity, require that seat seals be designed around these characteristics. Therefore, when the sealing material becomes hard, the reliability of the sealing is damaged. Moreover, Teflon has a low temperature resistance grade and can only be used under the condition of less than 180℃.Beyond this temperature, the sealing material will age. In the case of long-term use, it is generally only used at 120℃. (2) its regulating performance relative to the globe valve to some poor, especially pneumatic valve (or electric valve)